Prefer podcasting? Check out Episode 4: Tea Processing (1/2): Time, Heat, and Pressure of The Hideaway Tea Pod.

As Magical as the Potato

I present the potato. It’s baked, fried, ground, roasted, mashed, puréed, steamed, and boiled (to name a few). In other words, we interact with our food in as many creative ways as we can manifest. Over the span of centuries, we’ve done the same with tea leaves and continue to process them by using age-old artisanal methods to produce various wildly complex and aromatic teas. This begs the question – how exactly does the tea plant of the forest become the beverage in our hands and why does whatever we’re doing work? Today we’re scratching the surface, traveling the tea leaf’s journey, and breaking down the science of tea-processing. Let’s dive right in.

A Recipe For Tea

The Camelia sinensis plant gives us green, white, yellow, oolong, black, and puer tea. Even further varieties exist under each major tea type, and every tea artisan around the globe treats the tea leaf uniquely (hence artisan). Nevertheless, all tea-processing methods follow a similar pattern. Like cooking and in no particular order, tea-processing involves time, heat, and pressure. Let’s take a closer look at our ingredients.

A Tablespoon of Time

You probably think I’m silly for even mentioning that tea-processing (like everything else) takes time. In fact, tea artisans utilize time quite intentionally as a means of controlling their tea leaf’s chemical transformation upon plucking.

Withering

A plucked tea leaf is immediately left to wither under the sun or in a processing facility for some set period of time. Detached from its source of nutrients, the tea leaf softens, its cell membranes deteriorate, and chlorophyll production ceases. A percentage of the tea leaf’s moisture content evaporates and the tea leaf grows pliable, becoming much more twistable, squeezable, and rollable for subsequent tea-processing phases. During withering, a flurry of additional chemical reactions occur – the concentration of caffeine increases, proteins are broken down into free amino acids, chlorophyll content degrades, and volatile flavor compounds form [1] [2].

Oxidation

As the tea leaf’s membranes continue to degrade, internal enzymes become exposed to the open air and to oxygen, causing a chemical process called oxidation. When exposed to oxygen, an enzyme polyphenol oxidase (PPO) triggers the transformation of phenolic compounds into quinones. These quinones then further react with other quinones and phenolics within the leaf to generate melanin [3]. This wild chain reaction is known as enzymatic browning and is the same familiar process that occurs to a sliced apple or avocado when exposed to open air. A master tea artisan monitors and controls this oxidation process so that tea leaves undergo oxidation only to some predetermined extent.

These major changes collectively create a complex aroma, flavor, and color in a tea. And this is only the beginning.

Fermentation

Oxidation and fermentation are often used interchangeably within the tea world, and this can cause confusion regarding what actually happens in a tea leaf during processing. This linguistic habit is possibly rooted in humanity’s much longer history and use of true fermentation in breads, wines, and other beverages (est. since early human civilization, roughly 10,000 BC [4]). More practically, to the naked eye, fermentation and oxidation seem similar – in food preparation, both processes involve ‘leaving it alone for a while’, so it makes sense that one would describe the natural withering and browning of tea leaves as fermentation. By the time oxidation was discovered in the late 18th century, language revolving around tea-production had long been well-established for millenniums and generational tea producers might’ve simply chosen to continue their contextual use of ‘fermentation’.

Before moving further, let’s dispel any lingering confusion – only the production of certain teas involves true fermentation. In contrast to oxidation, which is an enzymatic reaction involving oxygen, fermentation is an anaerobic process involving a food’s altered chemical composition through microbial activity (ex. yeast, bacteria, mold). In other words, all teas are oxidized to some extent during processing, however only teas altered by microorganisms (yellow and ripe puer teas) are truly fermented.

Now we understand the semantic difference between oxidation and fermentation. Still, I believe there’s no harm in reading between the lines whenever a fellow tea friend mentions fermentation out of context!

A Heap of Heat

Although the most fundamental purpose of cooking is to soften, break down, and sanitize food for safe consumption, many more reactions occur alongside the application of heat to food. Beyond food safety, heat makes food and tea delicious.

Tea leaves are commonly processed via heat through pan-firing (roasted and tossed in a heated pan), sun-drying, baking, and steaming. These heating methods can involve…

- Dehydration – Most evidently, dry heat causes water content in a tea leaf to evaporate. Simply, where there is water, there is life. Conversely, dehydration inhibits biological action, prevents the growth of bacteria, yeast, and mold, and extends shelf life.

- Flavor Development – Some dry heating methods introduce further flavor development through the Malliard reaction, a chemical process in cooking where amino acids react with reducing sugars to develop desirable browning, aromas, and flavors (ex. the searing of a steak).

- Halting Oxidation – Heat denatures or ‘malfunctions’ polyphenol oxidase (PPO), the enzyme responsible for oxidation, and ‘fixes’ the tea leaf in its state of oxidation. This step most definitively determines the tea type (green, white, yellow, oolong, black, puer) that is being produced.

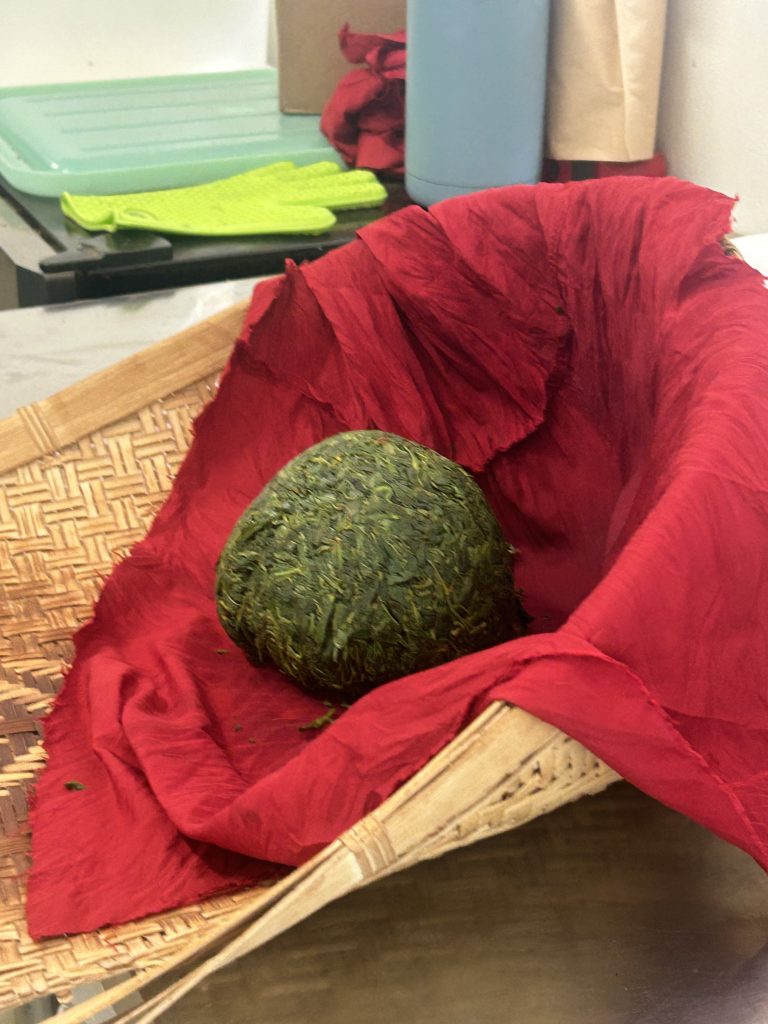

A Pinch of Pressure

Lastly, pressure. How do we usually get close up and personal with our tea leaves (before drinking their infusions, of course)? Our human hands make careful contact along the tea leaf’s entire journey, from plucking and sorting to caking and packaging. For the purposes of this article, let’s narrow down our scope to more clearly understand how only a couple well-known methods of applied pressure can shape our tea leaves and further intensify the oxidation process.

Rolling

A major method of applied pressure is rolling, where bulk tea leaves are physically twisted and squeezed by hand or machine into slender strips, “leading to the adequate mixing of substrates with enzymes and promoting…subsequent biochemical reactions” [5].

One study revealed that even the degree of applied rolling pressure can impact leaf oxidation and, as a result, influence a finished tea’s flavor quality (sweetness, sourness, bitterness, and umami) and color [5]. The study’s observations noted that loose-leaf tea treated under ‘moderate-pressure rolling’ (MPR) produced the highest quality tea when compared to teas treated with ‘low’ or ‘high-pressure rolling’ (LPR, HPR):

- [Less sourness] “Phenolic acids…are one important class of phenolic constituents in tea, which are responsible for the sourness and astringency taste in black tea…MPR resulted in the lowest concentrations of phenolic acids”.

- [Moderate color, moderate luminance] “Compared to LPR, the congou black tea produced by HPR and MPR showed significantly higher values of a* (redness), b* (yellowness) and C* (color saturation), which…steadily rose along with the increased pressure. However, the value of L* (luminance) was significantly reduced with the upward rolling pressure”.

- [Less bitterness] “…the MPR-treated black tea presented lowest levels of some astringent and bitter substances, while HPR and LPR resulted in the accumulation of those unpleasant substances.”

Crush-Tear-Curl

Contrasting the artisanal, nuanced production method of loose-leaf tea, the Crush-Tear-Curl (CTC) production method allows for fast mass production of standardized tea. In CTC tea production, bulk tea leaves are uniformly “crushed, torn, and curled” by serrated machines into small pellet-sized pieces. Despite natural annual and seasonal changes in tea leaf flavor from any one source, CTC tea producers can formulate blends of ground tea leaves from numerous sources in order to meet target flavor profiles each year. As a result, CTC teas are (intended to be) low-cost, more easily producible and distributable teas for all to afford and consistently enjoy.

And Voilà!

Some tea leaves, a tablespoon of time, a heap of heat, a pinch of pressure, and we have our cup of tea!

Along my own tea journey, I’ve learned that the more I truly know tea, the more I fall in love with, appreciate, and honor it. And isn’t that true of anything or anyone? Today, we’ve built upon our relationship with tea and, more broadly, with our food. We now better understand the mechanisms through which humanity has interacted with and prepared the Camellia sinensis plant for centuries. Having just been equipped with this knowledge, we’re ready to dive into Part 2 of this tea-processing mini-series. We’ll discover how each of these elements – time, heat, and pressure – is used to produce each major tea type, and we’ll learn what makes each tea type so special. See you soon in Tea Processing (2/2) : Every Tea Present and Accounted For!

References

- Muthumani, T., & Senthil Kumar, R. S. (2007). Studies on freeze-withering in black tea manufacturing. Food Chemistry, 101(1), 103–106. https://doi.org/10.1016/j.foodchem.2006.01.007

- Deb, S., & Jolvis Pou, K. R. (2016). A Review of Withering in the Processing of Black Tea. Journal of Biosystems Engineering, 41(4), 365–372. https://doi.org/10.5307/jbe.2016.41.4.365

- Yu, Y., Chen, D., Li, W., Mou, Y., Geng, Y., Chen, F., Hu, X., Ji, J., & Ma, L. (2023). Quinone reactivity: Investigation of their contribution to nonenzymatic browning. Food Frontiers, 4(2), 945–954. https://doi.org/10.1002/fft2.247

- Eder, M. (2023, November 17). History of Fermentation: The journey from brewing to advanced therapies. Single Use Support. https://www.susupport.com/knowledge/fermentation/history-fermentation-journey-from-brewing-advanced-therapies

- Zhang, S., Wu, S., Yu, Q., Shan, X., Chen, L., Deng, Y., Hua, J., Zhu, J., Zhou, Q., Jiang, Y., Yuan, H., & Li, J. (2023). The influence of rolling pressure on the changes in non-volatile compounds and sensory quality of congou black tea: The combination of metabolomics, E-tongue, and chromatic differences analyses. Food Chemistry: X, 20, 100989. https://doi.org/10.1016/j.fochx.2023.100989